Introduction of Auto Grease Pump?

An automatic grease pump is a device that automatically dispenses lubricant (grease) to machinery or equipment. It is typically used in industrial settings to ensure that machinery is properly lubricated, reducing friction and wear, and extending its lifespan. The pump is usually connected to a grease reservoir or grease cartridge and operates using a timer or pressure-sensitive device to deliver grease to the specified lubrication points.

What benefits of Auto Grease Pump?

For best results, an automatic grease pump should be installed and configured properly, with the right type of grease, appropriate grease flow rate, and effective control and monitoring systems. It is also important to regularly inspect and maintain the pump and lubrication system to ensure that it continues to operate efficiently. Benefits of an automatic grease pump:

-

Consistent lubrication: Automatically dispenses grease at set intervals, ensuring that machinery is always properly lubricated.

-

Reduced maintenance: Lubrication is performed in a consistent and timely manner, reducing the need for manual maintenance checks.

-

Increased efficiency: Proper lubrication reduces friction and wear, increasing the efficiency and lifespan of machinery.

-

Time savings: Automated lubrication saves time and reduces labor costs compared to manual lubrication.

Auto Grease Pump System?

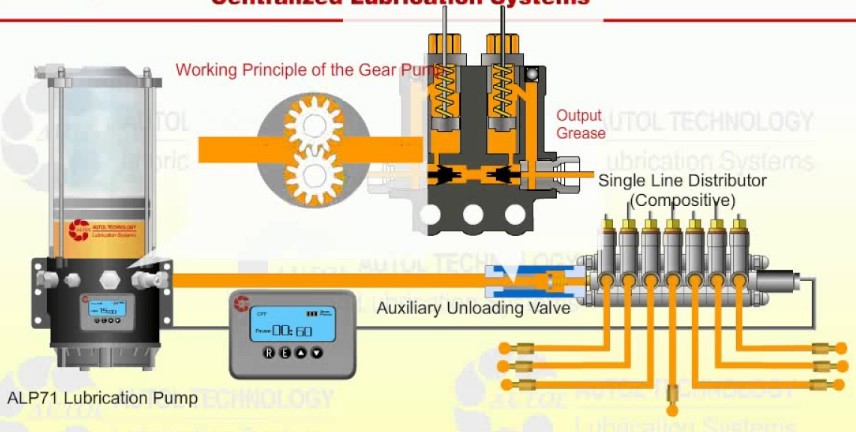

An automatic grease lubrication system is a device used to automatically apply lubricant (typically grease) to machinery and equipment, in order to reduce friction and wear. The system consists of several components, including:

-

A grease pump that delivers the lubricant to the system

-

A metering valve that controls the flow of lubricant

-

Lubricant lines that transport the lubricant to the lubrication points

-

Grease fittings or nipples that dispense the lubricant at the specified points

-

A control unit that manages the timing and sequence of the lubrication process The goal of the system is to ensure that machinery is properly lubricated and that maintenance is performed in a consistent and timely manner.

Grease Pump Pneumatic?

A pneumatic grease pump is a type of grease pump that uses compressed air as the power source to dispense lubricant (typically grease). The pump typically consists of an air-driven motor, a grease pump head, a grease discharge outlet, and an air control valve. When the pump is activated, the motor uses compressed air to create pressure that dispenses the grease through the discharge outlet and into the lubrication points. Pneumatic grease pumps are commonly used in industrial settings because they are versatile, reliable, and require relatively low maintenance.

Electric Grease Pump?

An electric grease pump is a type of grease pump that uses electricity as the power source to dispense lubricant (typically grease). The pump typically consists of an electric motor, a grease pump head, a grease discharge outlet, and an electrical control system. When the pump is activated, the electric motor creates pressure that dispenses the grease through the discharge outlet and into the lubrication points. Electric grease pumps are commonly used in industrial settings because they are efficient, easy to control, and can be connected to a central lubrication system to provide automated lubrication.

Lubrication Auto Grease Pump

Isohitech Lubrication is a manufacturer of automatic grease pumps. The company’s products are designed to provide automated lubrication to machinery and equipment in industrial settings. The specific features and specifications of Isohitech’s grease pumps may vary depending on the model, but they generally include:

-

Automatic dispensing of grease

-

Adjustable grease flow rate

-

Compatibility with various types of grease

-

Timer-based or pressure-based activation

-

Easy installation and integration with existing machinery

The products are designed to provide reliable and efficient lubrication, reducing friction and wear, and extending the lifespan of machinery. Isohitech offers a range of grease pump models to meet the needs of different industries and applications.

Here are a few manufacturers of automatic grease pumps:

-

Graco

-

Lincoln Industrial

-

SKF

-

Bijur Delimon

-

DropsA

-

Isohitech Lubrication

-

BECHEM Lubrication Technology

-

DropsA USA

-

ALEMITE

-

Jherico Industrial Note:

This is not an exhaustive list and there may be other manufacturers of automatic grease pumps not listed here. Read More – The Ultimate Guide to Industrial Cameras